Composition of cable machine equipment

Release time:

2020-05-09

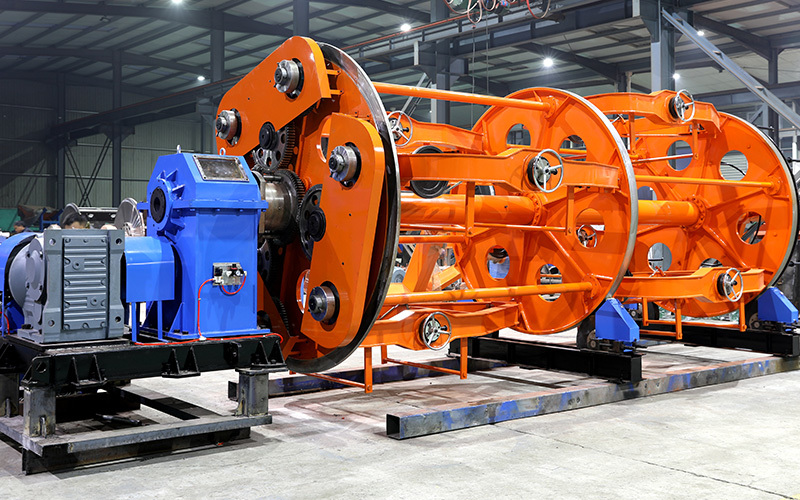

The structure of the winding cage is roughly similar to that of the winding machine, and there is a wire reel frame on which the insulating core reel is placed. Various types of cable machines have different numbers of wire trays. Large cable machines generally have 3 or 6 wire trays, while small cable machines can have 18 or 24 or even more wire trays.

pay-off rack, winding cage body, wire mold base, winding machine, armored machine, meter meter, traction device, winding rack, transmission system and electrical system.

The main components of the cable machine

1. Cage

The structure is roughly similar to the winding cage of the stranding machine, and there is a wire reel rack for insulating core discs on the winding cage. Various types of cable machines have different numbers of wire trays. Large cable machines generally have 3 or 6 wire trays, while small cable machines can have 18 or 24 or even more wire trays. There is a brake on each reel of the cage to control the tension of the core during twisting. The speed of the cage is adjusted by the speed change gear, and the direction of rotation can also be changed. There are some fixed support rods at the front of the cage to place the filler rope disc.

2. Mold base

The parallel die can be replaced as needed. Its function is to merge several insulated cores and twist them into the correct round cable.

3. Package leader

The structure is similar to that of the paper wrapping head. Generally, there are 3 or 6 belt clamps on the support back, which are used to wrap the tape, paper tape, glass cloth tape or film tape on the outside of the cable core.

4. Tractor

It is composed of a large-diameter wheel and a dial ring. The wire core moves in a straight line and has a part that can adjust the speed. The twisting pitch is mainly controlled by the speed of traction.

5. Wire take-up device

It is used to wind the twisted cable on the take-up reel, and the storage speed should be matched with the traction speed.

6. Place the stand for the centerline tool.

TAG:

Previous Page:

Next page:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province