Understanding Cable Stranding Machines: An Essential Overview

Release time:

2025-02-05

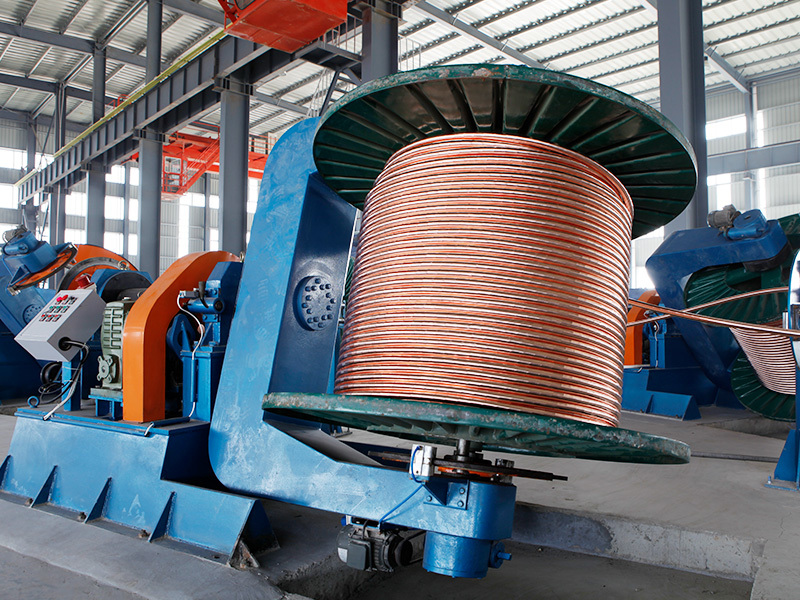

In the realm of electrical and electronic product manufacturing, cable stranding machines play a crucial role. These machines are specifically designed to intertwine multiple strands of wire or fiber into a single composite cable. This process is fundamental for enhancing the electrical conductivity, flexibility, and durability of the final product. One of the primary functions of a cable strandi

One of the primary functions of a cable stranding machine is to combine various wire strands in a precise manner, ensuring that the resulting cable meets specific industry standards. The stranding process can involve different configurations, such as concentric, layer or helical stranding, depending on the intended application of the cable. For example, cables used in power transmission often require a different stranding technique compared to those used in telecommunications.

Cable stranding machines operate using advanced technology that allows for accurate control over the tension and speed of the strands being twisted together. This ensures a uniform and consistent quality throughout the length of the cable. Modern machines are typically equipped with features such as automatic feeding systems, tension control mechanisms, and monitoring devices that track operational parameters in real time. Such innovations enhance productivity and reduce the likelihood of defects in the manufacturing process.

One key advantage of using a cable stranding machine is its ability to produce cables with a high level of flexibility. The interwoven structure of the cable allows for better performance in applications that require bending or movement. This is particularly important in industries such as automotive and robotics, where cables are often subjected to dynamic conditions.

Maintenance of cable stranding machines is also a critical aspect that manufacturers must consider. Regular inspections and servicing are necessary to ensure that the machines operate efficiently and to prolong their lifespan. Common maintenance tasks include lubricating moving parts, checking for wear and tear, and calibrating the machine settings to match production requirements.

In conclusion, cable stranding machines are indispensable in the manufacturing of modern electrical and electronic products. They not only improve the quality and reliability of cables but also enhance the overall efficiency of the production process. Understanding the functionalities and benefits of these machines can help manufacturers make informed decisions when selecting equipment for their production lines. By investing in advanced cable stranding technology, businesses can achieve higher output, better product quality, and ultimately greater customer satisfaction.

TAG:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province